Reducing seafood waste by repurposing bones, teeth, and skin into designer jewelry & accessories

Pacific bigeye tuna skins that have been hand-tanned to become fish leather. Photo by Melanie Maggio.

In 2015, I walked away from a thrilling career in fashion footwear design. In many ways it was my dream job – I was truly passionate about the work I did, and loved the opportunity to design alongside some incredible people. But I became increasingly convinced that there was something intrinsically wasteful about an industry that was consuming raw materials in such huge volumes, overproducing styles and designs as it chased trends in a fast fashion retail market.

I wanted to be part of the solution, not part of the problem. I knew instinctively that, by being innovative and creative, I could design around an upcycled material that would alleviate waste instead of contributing to it.

My search took me to Florida, where my partner was making a TV show about spearfishermen. I had a chance to talk to one of the spearfishermen in a bar, who was wearing a cubera tooth that he’d caught. I asked him where all the byproducts went, like the bones and skin? His answer: “Mainly it just gets tossed in the trash.”

I was shocked to get an understanding of yield, or the amount of meat we remove relative to the entire fish. Sometimes the parts that are wasted, including the skin and bones that I work with, make up more than half of a single fish, by weight. When you think about how much fish is caught annually in the U.S. (nearly 5 million tons in 2016), the scale of waste can be enormous.[1]

I set out to start designing around these materials and that’s how I came to launch a fashion-forward, upcycled jewelry brand called Jacto (the word is Latin, meaning “to throw out”). I source pieces of bone, skin, and teeth that would otherwise be discarded from sustainable fisheries, and transport them to a taxidermist who uses flesh-eating beetles, called dermestids, to clean the bones naturally, without the need for water waste or harmful chemicals.

Yes, I did just say flesh-eating beetles! The profoundly beautiful results are then upcycled and designed into pieces of sustainable jewelry and accessories, made by hand in New York City.

I choose each piece of bone based on the quality and how well the size and shape fit the item I want to use it for, thoughtfully reimagining how it could become a striking statement on an ear, neckline, or hand. Each fragment is unique, and special in its own way – some perfectly symmetrical, others with flaws that reveal unexpected beauty. The challenge – in contrast to the rest of the fashion industry – is in working out what each piece will become. Instead of chasing each season’s trend – geometric one minute, bold or minimalist the next – I’m reliant on the raw materials for inspiration, and that’s where things get really exciting for me, as a designer.

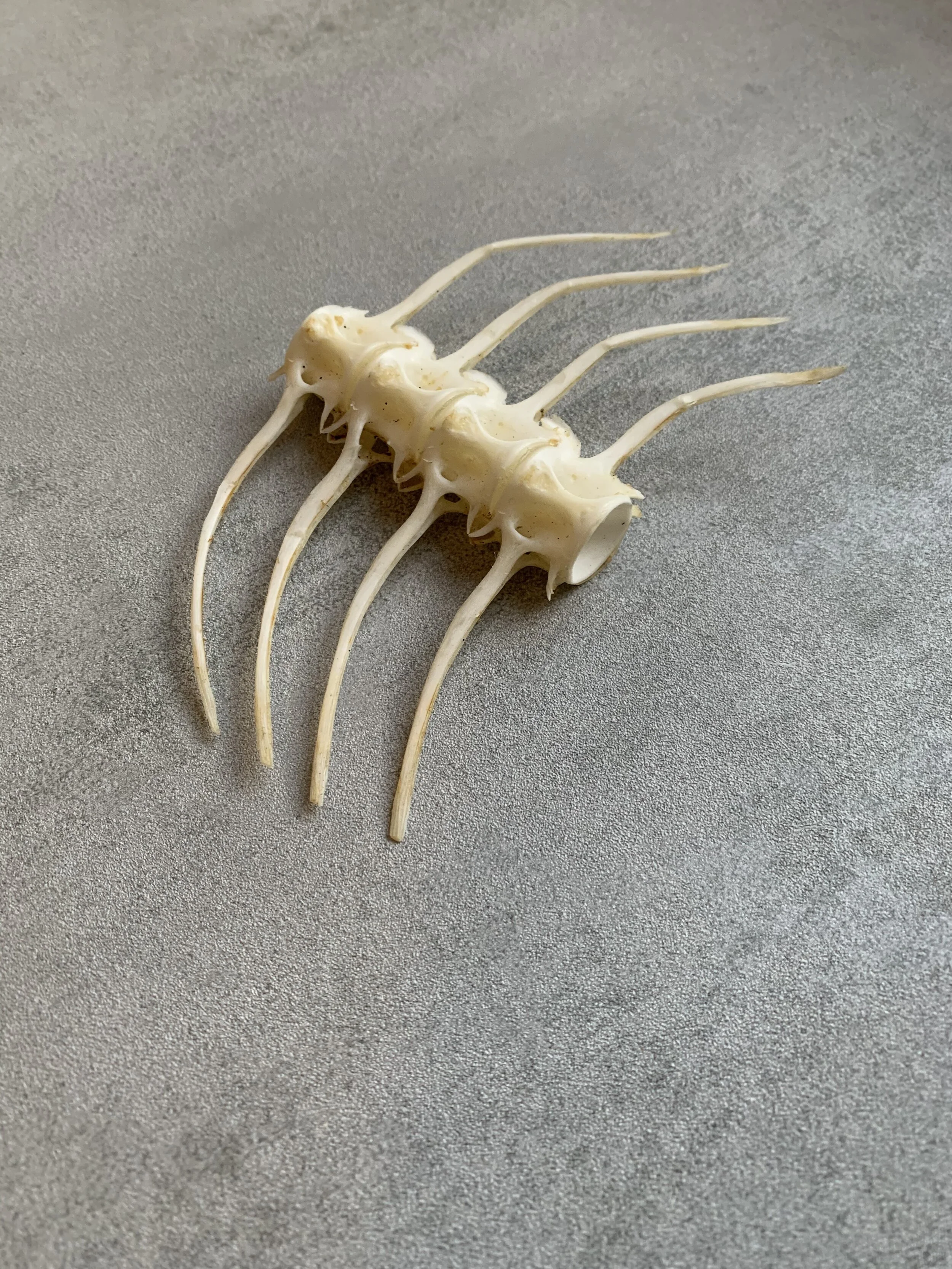

The design process visualized - from a piece of bigeye tuna spinal column to a one-of-a-kind jump ring. All photos by Melanie Maggio.

Sometimes the shape will be great, but might not be the right size. Sometimes it’ll be beautiful, but too fragile to wear. Other times it might not fit into any design I’m working on, but will be perfect for a piece at some point in the future. Every challenge is an opportunity to find potential – and to use the existing raw material nature has given me, rather than consume more products.

Using a small hand saw, I shape the bones – the largest pieces becoming statement ornaments for home decor. Barracuda jaws become large pendants; smaller bones from the mangrove snapper and red snapper are more suited to delicate necklaces; teeth become earrings, and the otolith from the tilefish (a small bone similar to an eardrum) is a ring with an incredible back story.

If a bone is particularly fragile, I make molds, which are then used to produce cast replicas. If a tooth is missing, the gap can become a perfectly sized space to thread the chain or a jump ring through. And the skins that I’m able to sustainably tan from my studio become bracelets or wallets. Nothing goes to waste – there’s usually something unique in most pieces (although some parts sit in a drawer, waiting for a future collection’s inspiration).

For the Fishful Future project, I’m tanning tuna skins from my studio in Williamsburg. Starting with removing the scales and taking off any remaining scraps of meat, the skins are first washed in soap and water, then, to soften them and give them protein, I soak them overnight in a cup of vegetable oil mixed with egg and a little more soap (I use an all-natural, scented Castile soap to help take away the fishy smell!).

In the morning, I hang them out in the sun and, once dry, work them back and forth against a metal edge until they’re soft and supple. It’s a labor-intensive process, and every skin is different, so it takes some trial and error to get perfect. But the results are worth it – a one-of-a-kind, limited edition leather key fob combined with a quality brass keyring and hardware set, with an option to add a brass cast of tuna vertebrae.

This product is a collaborative design with Cynthia, Fishful Future’s project associate and co-owner of Giovanni Rose Handcrafted Creations. We are highlighting the durability of fish skin leather, the beauty of what is traditionally considered waste, and the commercial fishing industry that produces the raw material. The design combines form, function, and beauty with an underlying message of full utilization. Cynthia is handling the leather working aspect by cutting and assembling the leather key fob with my hand-tanned tuna skins.

All the metal I use is 100% recycled, free from nickel and harsh alloys, and can be customized to an individual’s taste – polished, matte, or recreated in solid gold. Packaged in a luxuriously soft pouch and statement tin, each piece comes with a unique story of the fish it came from, and opens up a conversation about the way we as consumers see the amazing yet limited resources of our planet.

Designed with a zero-waste ethos, the Tuna Leather Key Ring & Tuna Vertebrae Necklace are striking statement pieces designed to start conversations and bring new value to these otherwise regularly discarded fish bones and skin.

The keyring and necklace are the result of collaboration months in the making between Jacto and Giovanni Rose Handcrafted Creations, a relationship fostered by shared values, and a San Diego-based collaborative initiative called Fishful Future. The aim of this collaboration is to highlight the striking beauty and durable functionality of fish skin leather, which is typically discarded as waste in the commercial fishing industry. Our designs combine form, function, and beauty with an underlying message of full utilization and support for U.S. commercial fishing.

The bigeye tuna (Thunnus obesus) bones and skin are sustainably sourced from fishermen in San Diego, expertly tanned by hand in NYC, and the leather keyring is meticulously handmade in San Diego. The bones are upcycled and naturally cleaned in our Brooklyn Studio and cast in the NYC jewelry district. Please note that leather is a natural material - there is variance between key rings. Over time with use, you will notice the leather naturally ages. This is 100% normal and to be expected.

Tuna leather key rings and tuna vertebrae necklaces are now available to order through ShopJacto.com

References

The State of World Fisheries and Aquaculture, 2016. Food and Agriculture Association of the United Nations. http://www.fao.org/3/i5555e/i5555e.pdf